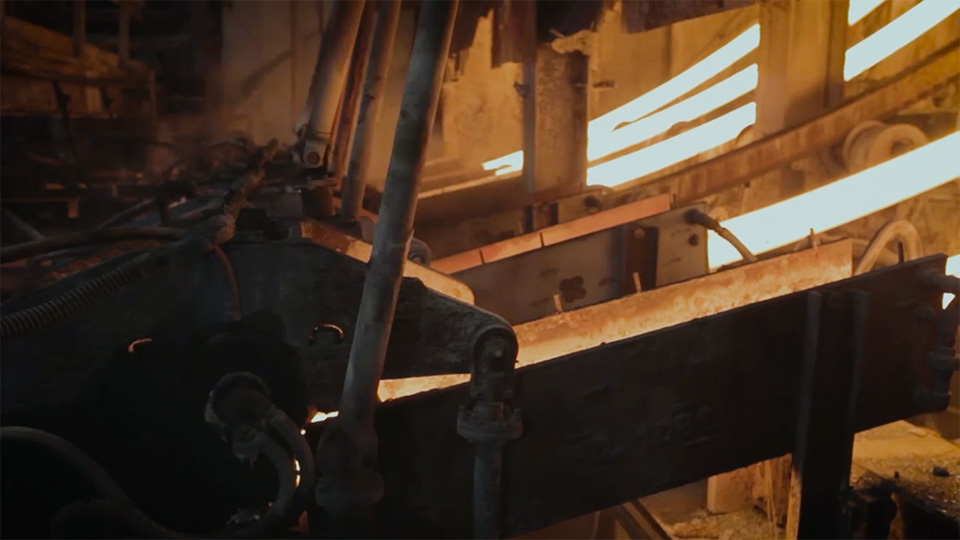

For over 125 years, Liberty has been a leader in the steel industry. Located in Peoria, Illinois, the facility is one of the largest wire and rod mills in the US. We produce 700,000 tons of steel each year. A major recycler, much of Liberty’s steel is manufactured from reprocessed steel. The metal is melted, purified, refined and poured on site.

Liberty’s domestic advantage is substantial. It means that every ounce of steel is closely monitored to eliminate impurities and maintain specific alloy formulas. As a result, the process assures consistency every time. And, since our products are 100% American-made, LSW steel is Buy America Compliant. LSW has made a multi-million dollar investment to our rod and wire mills. This enables us to produce some of the most exacting high carbon and CHQ grade steel and wire products. Finished materials include billet, rod, rebar and industrial wire. Liberty production practices are nimble and flexible. Therefore, we are capable of offering customized grades of steel to meet individual customer needs quickly and efficiently. For example, Liberty has over 20 steel grades that are classified as 1008 steel. We work closely with our customers to help control inventory lead times while meeting exacting specifications for every pound of steel created.Contact us for additional information on Liberty Steel & Wire or to request a quote.

Billet

Liberty’s continuous billet caster uses state-of-the-art clean steel practices, yielding consistent, high-quality steel billets. Our large production capacity enables us to meet the volume demands of all our customers.Product/Application Sell Sheet

Rebar

Liberty rebar products are produced with the same quality and consistency expected in Liberty steel. Our integrated steel mill allows us continuous control from beginning to end, enabling LSW to produce the finest rebar products possible.Product/Application Sell Sheet

Rod

Liberty’s Rod Mill facility features a Morgan® No-Twist finishing mill for consistent rod quality. Retarded cooling provides system flexibility to meet a variety of end product specifications.Product/Application Sell Sheet

Industrial Wire

With 22 different drawing machines for customer specifications, LSW’s extensive wire drawing capabilities make it a leader in the wire industry, with each product produced in accordance with applicable ASTM standards.Product/Application Sell Sheet

Agricultural Fence

The only ag fence completely made in the U.S. from start to finish, Red Brand’s use of high-quality materials and expert craftsmanship have earned LSW-manufactured Red Brand the reputation of ‘the most respected name in farm fence.’Product/Application Sell Sheet

Capabilities

Liberty Steel & Wire in Peoria, Illinois, produces steel that is Buy America Compliant. Every ounce of steel is closely monitored from the processing of scrap metal through final packaging to assure quality and consistency.Billet

Liberty’s continuous billet caster uses state-of-the-art clean steel practices, yielding consistent, high-quality steel billets. Our large production capacity enables us to meet the volume demands of all our customers.Product/Application Sell Sheet

Rebar

Liberty rebar products are produced with the same quality and consistency expected in Liberty steel. Our integrated steel mill allows us continuous control from beginning to end, enabling LSW to produce the finest rebar products possible.Product/Application Sell Sheet

Rod

Liberty’s Rod Mill facility features a Morgan&red; No-Twist finishing mill for consistent rod quality. Retarded cooling provides system flexibility to meet a variety of end product specifications.Product/Application Sell Sheet

Industrial Wire

With 22 different drawing machines for customer specifications, LSW’s extensive wire drawing capabilities make it a leader in the wire industry, with each product produced in accordance with applicable ASTM standards.Product/Application Sell Sheet